Why Hollow Blocks Are the Secret to Greener Buildings in the UAE

Every developer, contractor, and project manager knows that the right block choice can make or break a project’s durability and efficiency.

That’s where concrete blocks, particularly hollow blocks , solid, and insulated varieties come in. They’re not just building materials anymore; they’re engineered solutions designed to balance strength, thermal comfort, and sustainability.

At Ducon Industries, we take that balance seriously. With 24/7 operations and an unmatched 4-hour delivery promise, we make sure your site never stops.

Whether it’s a high-rise in Downtown Dubai or a residential compound in Sharjah, we deliver the right blocks, on time, every time with consistent quality and environmental responsibility built in.

In this guide, we’ll break down everything you need to know about hollow, solid, and insulated blocks, how they differ, and how to choose the right one for your project with sustainability at the core.

1. What Exactly Are Concrete Blocks?

Concrete blocks are the backbone of masonry construction. Versatile, durable, and modular.

They’re made by compacting a mixture of cement, aggregates, and water into molds, then curing them to achieve structural strength.

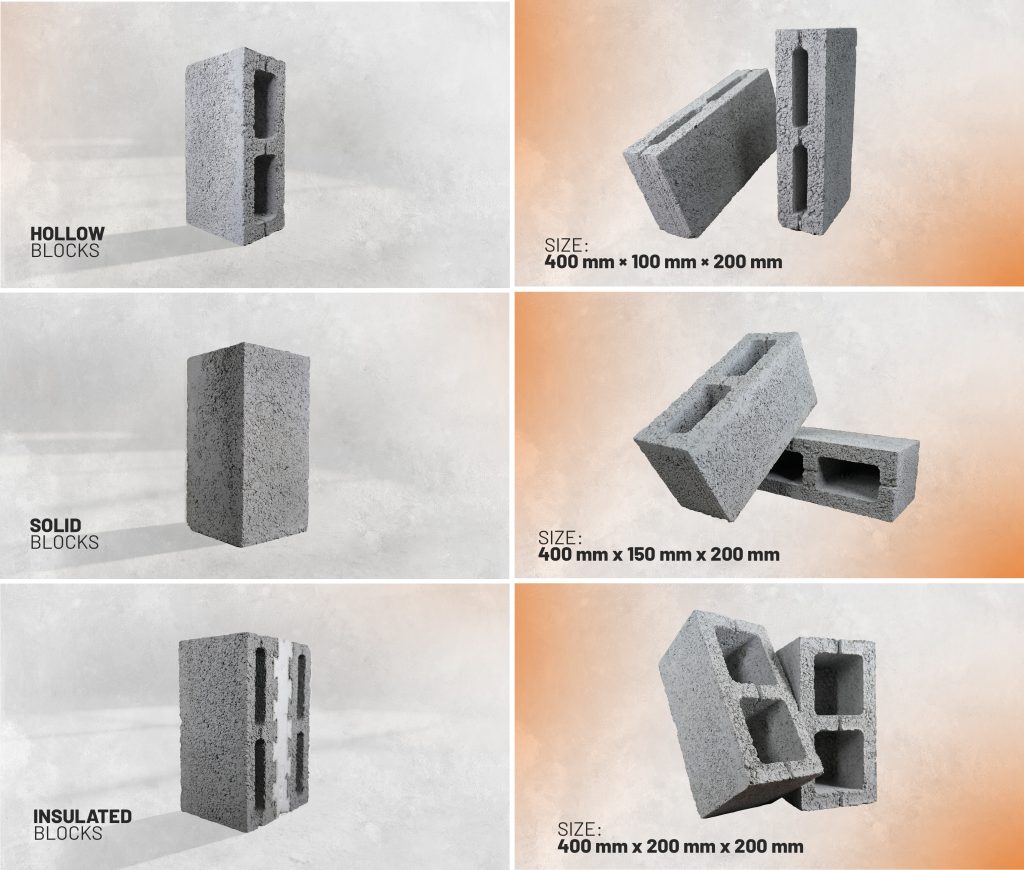

Most blocks used in UAE projects fall into three categories:

Hollow blocks (also known as block hollow)

Solid blocks

Insulated or thermal blocks

Each serves a specific purpose, from load-bearing walls to energy-efficient facades, and understanding the difference helps architects and engineers optimize both cost and performance.

2. Block Hollow: Lightweight Strength for Modern Construction

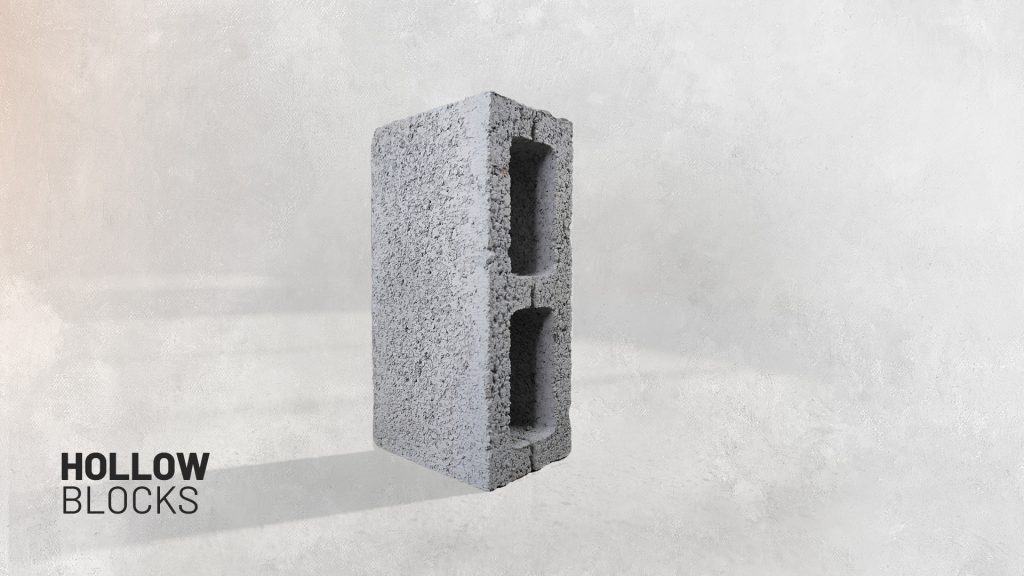

What Is a Hollow Block?

A hollow block (or hollow concrete block) contains two or more hollow cores or voids, reducing its overall weight without compromising strength. These voids also provide space for insulation or reinforcement bars (rebars), making them adaptable for both structural and non-structural walls.

Typical sizes include:

4″ Inch Hollow Block : 400 mm × 100 mm × 200 mm

6″ Inch Hollow Block : 400 mm x 150 mm x 200 mm

8″ Inch Hollow Block : 400 mm x 200 mm x 200 mm

Key Advantages

- Lightweight yet strong – The hollow cores reduce dead load, making transportation, handling, and installation easier.

2. Thermal and sound insulation – Air pockets act as natural insulators, improving indoor comfort.

3. Material efficiency – Less concrete per block means lower material usage and cost.

4. Sustainability – Fewer raw materials and easier recyclability lower environmental impact.

5. Design flexibility – The hollow centers can accommodate reinforcement, conduits, or insulation foam inserts.

Applications in UAE Projects

Hollow blocks are widely used for:

- External and internal walls in villas, apartments, and commercial buildings

- Partition walls in non-load-bearing systems

- Boundary walls and fences

- Retaining walls (with reinforcement)

For fast-paced UAE construction, hollow block systems are a preferred choice. They balance speed, structural reliability, and long-term sustainability.

3. Solid Concrete Blocks: The Traditional Powerhouse

If hollow blocks represent efficiency, solid blocks represent strength. These blocks are fully compacted with no cavities, giving them higher compressive strength and density.

Why Use Solid Blocks?

High load-bearing capacity – Ideal for foundations, retaining walls, and heavy structures.

Durability – With fewer voids, they’re less prone to cracking under stress.

Fire resistance – Denser mass helps delay heat transfer.

Sound insulation – Excellent acoustic performance for industrial or commercial use.

The strength of solid blocks comes at a cost: they’re heavier, more material-intensive, and less thermally efficient than hollow types. For non-load-bearing walls, they can be over-engineered by adding unnecessary cost and weight.

In sustainable design, the key is balance: use solid blocks where strength is critical, and hollow blocks where efficiency and insulation matter more.

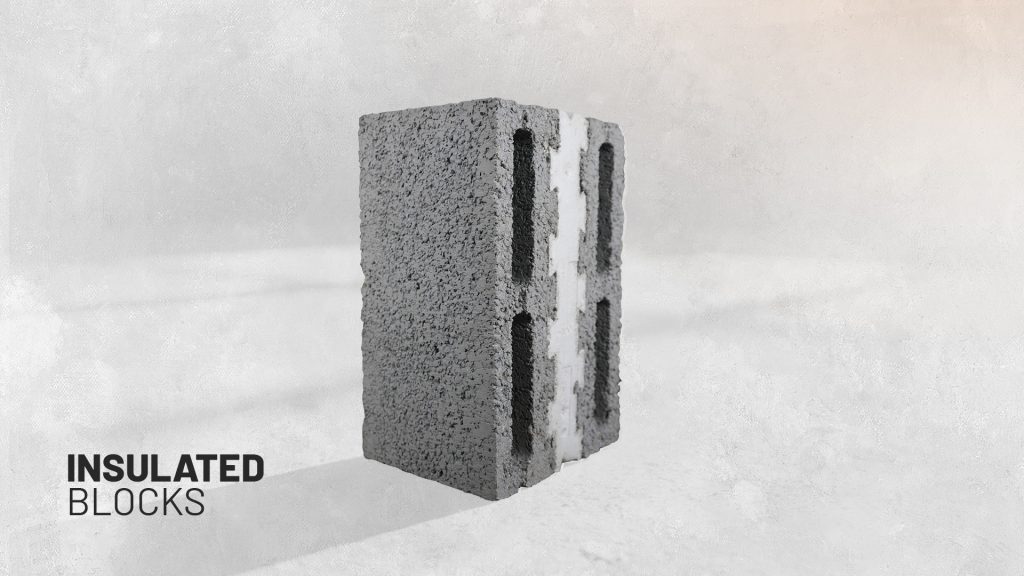

4. Insulated Concrete Blocks: Built for the UAE Climate

Dubai summers are no joke. The demand for energy-efficient walls has made insulated concrete blocks (ICBs) increasingly popular.

These blocks typically include thermal insulations, such as polystyrene (EPS) or polyurethane foam, sandwiched between layers of concrete. The result: dramatically reduced heat transfer, lower energy bills, and better indoor comfort.

Benefits of Insulated Blocks

- Thermal efficiency – Reduced heat gain keeps interiors cooler, minimizing air-conditioning load.

- Energy savings – Contributes to green building standards like Estidama (certifying the sustainability of buildings and communities in Abu Dhabi, UAE.) and LEED ( green building rating system developed by the U.S. Green Building Council).

- Soundproofing – Double-density layers provide better acoustic performance.

- Moisture resistance – Properly manufactured blocks resist condensation and mold.

Ducon’s Thermal Innovation

At Ducon, our insulated block line integrates high-performance insulation materials with precision molds. We optimize density, curing, and surface smoothness for easier plastering and maximum thermal resistance to ensure compliance with UAE energy codes and green building standards.

5. Comparison: Hollow vs. Solid vs. Insulated Blocks

Feature | Hollow Block | Solid Block | Insulated Block |

Weight | Light | Heavy | Moderate |

Strength | Medium to High | Very High | Medium |

Thermal Insulation | Moderate | Low | Excellent |

Material Use | Low | High | Medium |

Cost Efficiency | High | Moderate | Moderate |

Sustainability | High | Medium | Very High |

Best For | General walls, partitions | Foundations, retaining walls | Energy-efficient walls |

When choosing the right type, consider your project’s purpose, load demands, and energy goals. For most modern structures in the UAE, block hollow and insulated blocks strike the perfect balance between performance and sustainability.

6. Sustainability: The Core of Modern Block Manufacturing

- Smarter Raw Materials

Sustainability starts with sourcing. Ducon integrates recycled aggregates recycled water, reducing reliance on virgin materials while maintaining high compressive strength. - Energy & Water Efficiency

Our production plants are optimized for low energy consumption ensure minimal waste and emissions. Each block hollow we produce reflects a smaller carbon footprint compared to conventional methods. - Lifecycle Thinking

Concrete blocks are durable and fully recyclable. At end-of-life, they can be crushed and reused as sub-base or aggregate in new production, closing the sustainability loop.

7. The Ducon Advantage: Speed Meets Sustainability

In an industry where deadlines define reputation, Ducon has built its name on reliability.

24/7 Operations

We run round-the-clock manufacturing to meet urgent site demands, no idle time, no production gaps. Our teams coordinate directly with site engineers to schedule dispatches that align perfectly with pouring and laying cycles.

- Hour Delivery Promise

Our fleet covers every major emirate. Within four hours of confirmation, your order is on-site allowing contractors and developers to keep momentum without costly downtime.

- Unmatched Quality Assurance

From batching to curing, every block hollow and insulated unit passes through rigorous tests for dimensional accuracy, strength, and density..

- Client Consultation

Our technical team provides design guidance, testing support, and project consultations to ensure optimal block selection and installation.

8. Common Myths About Concrete Blocks

Myth #1: Hollow blocks are weak.

Not true. Properly manufactured hollow blocks offer compressive strength suitable for most structural walls. Their design simply optimizes material use.

Myth #2: Insulated blocks trap moisture.

Quality insulated blocks (like Ducon’s) have moisture barriers and low absorption rates — making them suitable for humid conditions.

Myth #3: Solid blocks are always stronger.

Strength depends on density and curing, not just solidity. Many hollow blocks outperform low-grade solid ones in tests.

Myth #4: Hollow blocks can’t be reinforced.

Their very design accommodates vertical and horizontal reinforcement, making them ideal for load-bearing walls when engineered correctly.

9. Why “Block Hollow” Is the Future of UAE Construction

With the UAE pushing for net-zero goals and green building codes, sustainable materials are no longer optional, they’re essential.

Hollow and insulated blocks allow architects to design structures that:

- Use fewer resources

- Reduce operational energy

Lower embodied carbon

Deliver long-term durability

Every block hollow used in your project brings tangible environmental and economic advantages from faster installation to better thermal comfort.

10. Building Tomorrow, Responsibly

Concrete blocks may seem simple, but they represent the foundation of modern, sustainable construction. The right choice whether hollow, solid, or insulated can improve efficiency, reduce emissions, and enhance overall building performance.

At Ducon Industries, we believe sustainability and reliability go hand in hand. With round-the-clock operations, 4-hour delivery, and an unmatched focus on quality, we help UAE builders achieve their goals faster and greener.

Ready to experience the Ducon difference?

Get in touch with our team to explore our full range of concrete block solutions and let’s build better, together.